DATE: 12-30-2025 – TIME: 1:50 – 4:20 ~ 2:30

Today was essentially a day continuing the process of flush riveting the Zenith 750 SD arm rest frames and making sure they fit in place in the jump seat location. While I did dimple the arm rest frame and the front and rear corner braces, I did not dimple the nutplates.

I purchased AN426AD5-4 rivets for the A5 (5/32) drilled holes and AN426AD3-4 rivets for the holes that were drilled for A3 (3/32) rivets for holding the nutplates in place. The AD rivet is a “hard” solid rivet. I’m not sure hard rivets are necessary especially as the solid rivets are stronger than the blind rivets to begin with but I figured it couldn’t hurt.

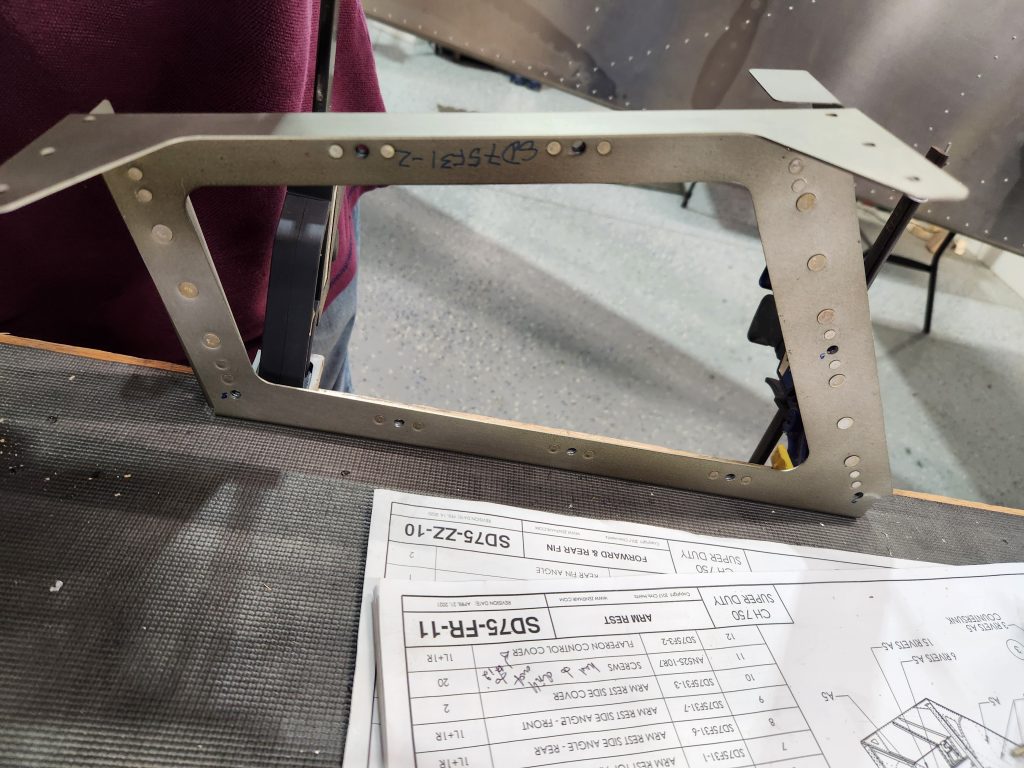

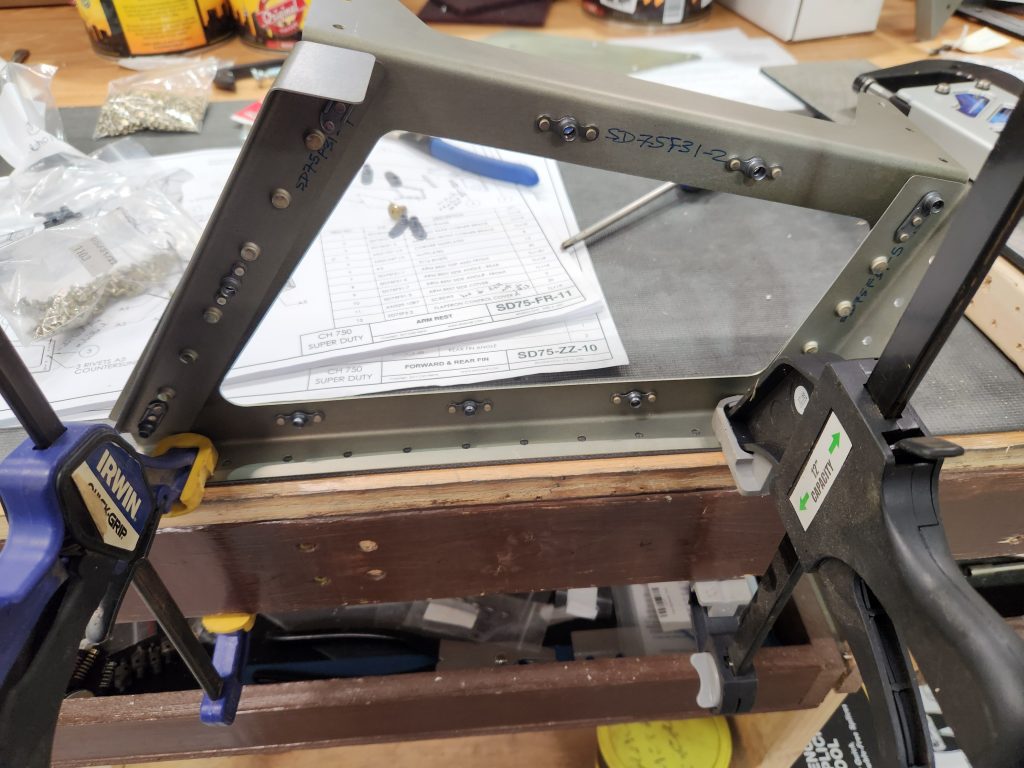

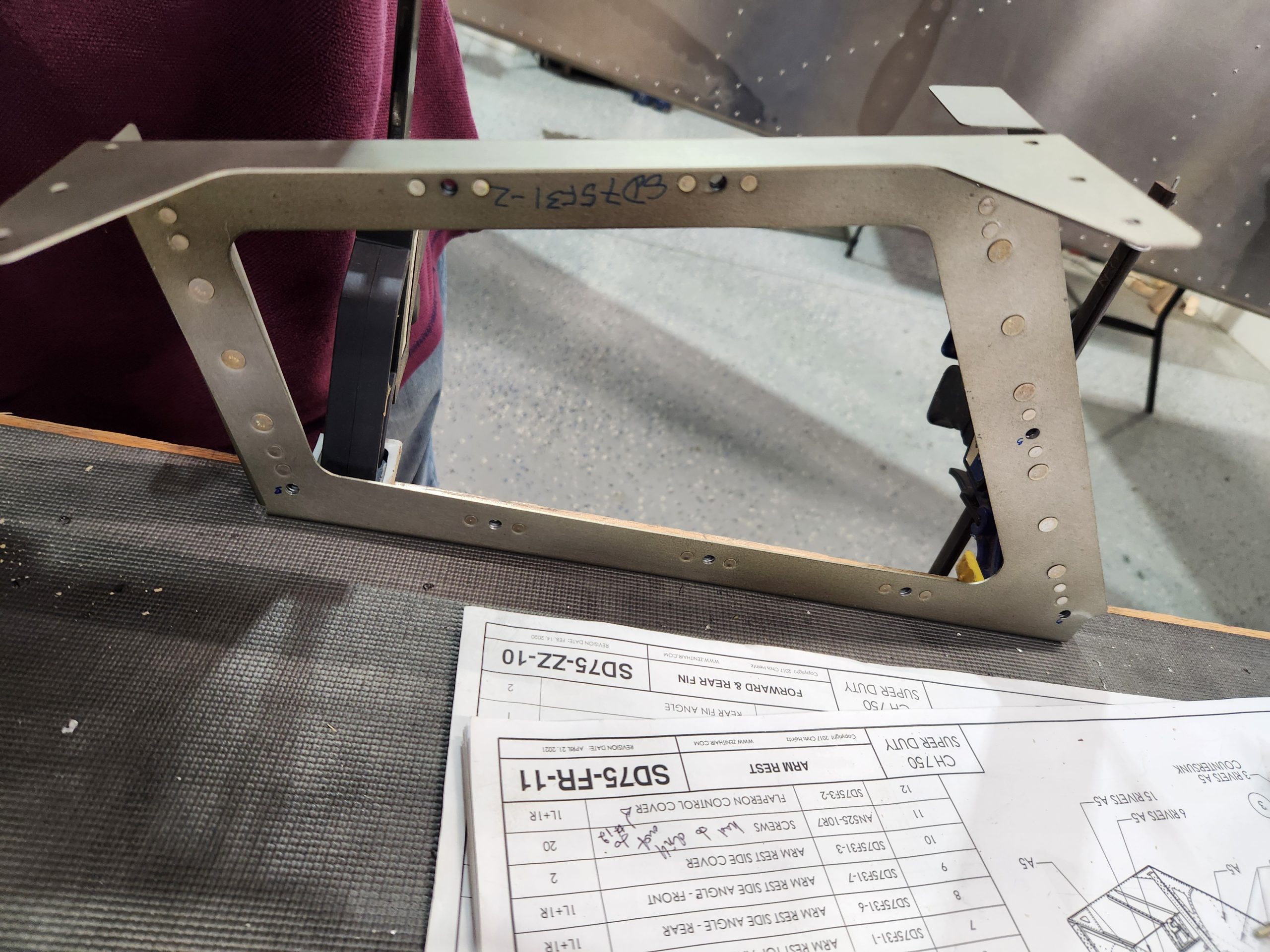

These snapshots are basically working at the bench flush riveting the arm rest corners and nutplates to the frame. They are high res so to some extent you can zoom in to see what they look like. At the bottom there are a couple of snapshots I took with my phone so you can see how they completed.

I did make a mess of a couple of rivets so you will see a snapshot of me drilling out the rivet. It is much more difficult to drill out a flush solid rivet than a blind rivet. I have found the easiest way to do this without making a mess of the hole is to punch the centre of the head of the rivet with a punch, use a slightly smaller drill bit than the hole size and hand turn the chuck with the drill bit in the punched hole initially which helps to prevent the drill bit skidding off the top of the rivet head.

Here are a couple of shots of the completed flush riveted arm rests.