DATE: 09-15-2025 – TIME: 2:17 – 3:25 ~ 1:10

I began today by just finished off the riveting of the bottom skin to the longerons and the diagonals. There are some holes, particularly in the longerons, that were not A5 that were labeled as A5 in the drawings but not in the IPL file.

I asked Roger via email what is correct and he said the drawing sizes are correct in all cases. This means drilling out the A4 holes to A5 with a #21 drill bit. The IPL sheets refer to them as #20 holes but #21 is the standard size per aviation and manufacturing guidelines (e.g., AC 43.13-1B for aircraft riveting).

Drilling out the holes with the skin already in place is going to leave some metal shavings between the skin and the longeron so it’s important to clean those out before riveting as they will hold the skin away from the longeron. I use a very thin piece of aluminum to do that but in most cases I try to do any drilling out before I need to so that I can use a deburr tool.

The left skin had the same hole misalignment of the right skin with SD75F18-4 so you will see me drilling out those two holes. These holes should probably be drilled out to A5 (#21), at least, because the hole in the diagonal is misaligned with the hole in the skin.

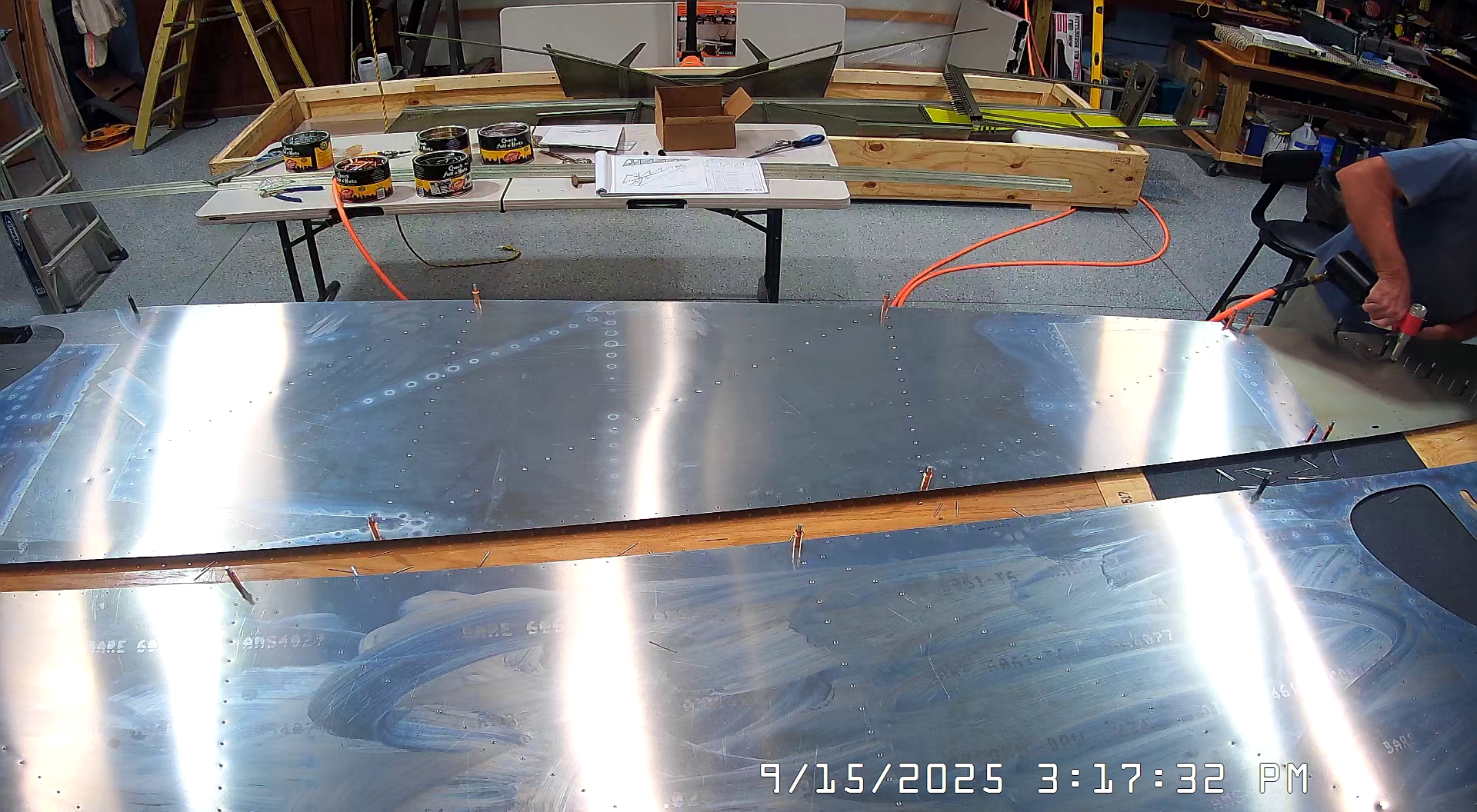

After completing the right side skin I just assembled the left side skin which was a lot quicker.

After finishing this I had to do some serious cleanup in the workshop to make space for starting on a couple of other sub-assemblies as I still did not have the steel parts I had sent out for powder coating and so did not want to start on attaching the side skins to the bottom skin.